Static inverters (called solid-state inverters) are manufactured in many types and models and can be classified according to the shape and power output capability of the AC output waveform. One of the most commonly used static inverters produces a stable sine wave output. The inverter converts low DC voltage to higher AC voltage. Static inverters are used to generate alternating current from direct current. In this case, the DC power comes from the battery. AC is generated by chopping DC into an approximately sinusoidal curve using power semiconductors.

The basic function of the inverter is to convert the DC current from the rectifier/charger or battery into an extremely accurate regulated AC output to power critical AC loads. Each inverter includes a static transfer switch and a manual bypass switch. The static inverter is actually the same as the UPS system. The difference is that the static inverter is configured to operate in "active standby" mode, and the bypass normally supplies power to the load. The static inverter adopts the design of the battery aging derating factor in order to obtain effective operation during the entire service life of the battery. The discharge capacity is a standard of 180 minutes.

The power electronic components used in solid-state inverters are ordinary thyristors (thyristor), turn-off thyristors (GTO), power field-effect transistors (P-MOSFET), high power transistors (GTR) and insulated gate bipolar transistors ( IGBT), etc. According to whether the commutation depends on AC power, it is divided into the active inverter and passive inverter. The active inverter converts DC energy into AC power with the same frequency as the AC power grid and feeds it back to the power grid. The passive inverter is to convert direct current into alternating current with a certain frequency or adjustable frequency to supply AC load.

The ordinary thyristor inverter requires a special converter circuit, which leads to a complicated main circuit structure. At present, inverter circuits composed of fully controlled devices with self-turn-off capabilities, such as GTR, GTO, and IGBT, are generally used and have simple structures and excellent performance. Active inverters are mainly used for DC power drag, cascade speed regulation of wire-wound asynchronous motors and high-voltage DC transmission. Passive inverters are mainly used for various inherent or variable frequency power supply devices, UPS, and AC frequency conversion speed control systems. At present, the output power of solid-state inverters can reach thousands of kilowatts or more, which is a widely used electrical energy conversion device.

Before the emergence of reliable and powerful semiconductors, the term "static" was used to distinguish these devices from the old methods of performing such tasks. Then it means using various forms of rotating machinery-electric motors, generators, and alternators. In many applications where continuous DC voltage must be converted to AC voltage, static inverters are used instead of rotating inverters or motor generators. The rapid development of the semiconductor industry has extended the range of applications for such devices to unrealistic voltage and power ranges a few years ago. These applications include power supplies for frequency-sensitive military and commercial AC equipment, aircraft emergency AC systems, and power supplies that convert a wide frequency range to precise frequencies.

The distribution of public power is carried out by the alternating current, or in rare cases, at a voltage level that allows operation under current conditions. In the case where the power distribution is direct current, it is associated with the presence of one or more accumulators, and the continuity of the power supply can be ensured even if the main power supply fails. In order to "convert" electrical energy from direct current to alternating with different characteristics of the distribution network, the device is called an inverter.

When a power failure occurs, use a contractor to transfer the backup battery to the inverter, and then support the load (depending on the application, usually 1 hour or 3 hours). This type of product is commonly used in emergency lighting applications. Although it can provide filtering or protection functions for more sensitive loads (such as computer equipment), it can provide effective backup and reduce operating costs. All our UPS modules can be configured as static inverters, but please note that this is a factory-installed option.

The AC output voltage is kept within a small voltage tolerance range, and the typical change is less than 1% when the input load changes completely. Output taps are usually provided to allow the selection of various voltages.

The significant advantage of using a static inverter system for emergency lighting is that it allows the use of various normal functional or decorative main luminaires as emergency accessories. The system does not require a separate low-voltage system or independent emergency lighting equipment. Static inverter emergency lighting system can meet the needs of a series of high-performance single-phase and three-phase static inverter systems, these systems are manufactured using the latest technology, can make your operation at ease.(Pure sine wave inverter PS series)

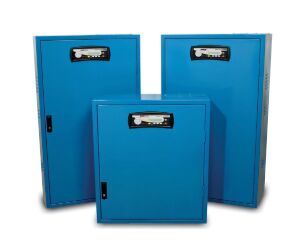

The static inverter system provides single-phase and three-phase input and single-phase output and three-phase output configurations to meet various needs and environments. For end-users and maintenance providers, these units are designed with simplicity in mind. Whether it is battery configuration or regular maintenance accessibility. In the event of a power failure, the system converts the DC current of the central battery to AC output.

The design of static inverters has lower requirements on system components because they cannot provide loads constantly. By using static switches or contactor bypass, the inverter is only loaded under mains failure or test conditions. Over time, this will greatly improve the performance of the components.

Static inverters are specifically designed to provide a retained output or combined retained/non-retained and switched-retained output. The static inverter must be able to clear the final circuit failure and can continue to operate without damaging its own circuit protection device, in order to meet the requirements of EN50171: 6.5.8.

The inverter is manufactured to a high standard and provides a cost-effective integrated solution for emergency power supply for escape and emergency lighting systems. The system requires at least 3 hours of autonomy and less than 24 hours of full charge (according to Other standby time is required).

To deal with this fault, the UPS will switch from battery operation to mains operation and then return to battery operation. However, if the main power failure occurs and the failure cannot be cleared, the UPS may stop working.

Static inverters, with controlled semiconductor switches and anti-parallel diodes, and a control device with a control device, are used to provide a current much higher than the rated current in the event of a short circuit in the consumer so that the consumer’s The fuse blows quickly in the circuit.

The anti-parallel thyristor is connected across the output of the inverter. When a short circuit occurs, the control device will take over the control of the ordinary inverter control device and switch the semiconductor switch between the two currents in the load circuit, where the higher current indicates the peak current limit of the semiconductor switch and the lower current It is located above the rated current. When the current limit is reached, the control module will block the semiconductor switch and trigger at least one thyristor to pass the current in the direction of the actual current.

Variations of this type of static inverter can be used, many of which provide square wave output. Because static inverters use solid-state components, they are smaller, more compact, and lighter than rotating inverters. Depending on the required output power rating, a static inverter no larger than a typical airspeed indicator can be used in the aircraft system. Some functions of the static inverter include:

1. High efficiency.

2. Low maintenance cost and long service life.

3. No warm-up period.

4. Able to start under load.

5. Extremely quiet operation.

6. Quickly respond to load changes.

During normal operation, the main power input is fed to the automatic transfer switching device (ATSD) through the system. During normal operation, the normally open contact closes, feeding mains into the load. At the same time, the main power supply is fed to the charger, so that the battery is fully charged, ready for emergency operations (such as in emergency lighting).

When the main power supply fails or exceeds specifications, ATSD will switch to its normally closed contact. The inverter starts and uses battery power to power the load. The static inverter will supply power to the load until utility power is restored or the battery is discharged.

When the mains is restored, ATSD will transfer the load back again, and the charger will charge the battery.

A microcontroller monitors all parameters in the system and will directly drive 10 LED indicators and a resettable audible alarm to indicate the system status.

The static inverters produced by SCIENTEK ELECTRICAL are designed to replace rotating electric generator sets and provide a maintenance-free solid-state solution that converts the DC power of the aircraft bus into the AC power required to operate motors and solid-state loads. The output of these inverters is a low distortion, adjusted, EMI filtered sine wave.

The multi-function solid-state inverter is designed for military and commercial fixed and rotary-wing aircraft to meet most airborne requirements.

The AC output is isolated from the DC input to suit any possible grounding scheme. The weight of these inverters is much smaller than their equivalent motor-generator sets, and the maintenance requirements for brushes and bearings are eliminated.

Due to the proprietary high-frequency pulsar circuit design, the efficiency remains constant over the entire input range.

All lower power inverters use ambient cooling, and some of them have passed QPL certification.

The high-performance static inverter is manufactured with the most advanced PWM and IGBT technology and can produce a pure sine wave output controlled by a microprocessor to deal with emergency lighting loads. True double-conversion and PWM technology. Including inverter-level output electrical isolation transformer. It can achieve 120% continuous overload, meet European standards, and the efficiency is as high as 91%

Emergency lighting regulations: parallel mode operation (optional) (hot standby, redundancy, symmetric parallel)

pure sine wave output

bigger 20Amp charger can charge the battery faster

maintenance bypass (used to completely isolate the inverter during maintenance)

nique inverter design can adapt to the high surge lighting load

ser selection of bypass loading (conversion mode)

CD panel provides accurate and detailed information about the following:

Loads, batteries, and inverters with advanced diagnostic functions.

The optional parallel control board

real-time clock and calendar indicator

Static inverter options:

Increase power through parallel operation

Increased reliability through 1 + 1 redundant operation

Extra battery modules extend autonomy

Wide area network management via SNMP.

emote monitoring panel RM-2000

Modbus connection for interface with BMS system

Main features of single-phase static inverter

Designed to meet the latest European EN50171 specifications

Real sine wave and PWM microprocessor control technology, the efficiency is as high as 97%

System and battery test functions

Can withstand 120% continuous overload, in line with European emergency lighting regulations

Larger charger to charge the battery faster. Superfast transition mode to battery mode

Two-way built-in power distribution panel (four-way optional)

The LCD panel provides accurate and detailed information about the load, battery, system diagnostics and manual test equipment, and audible alarms

RS232 and dry contacts for communication and remote monitoring of internal independent battery system

Generator compatible

Remote monitoring panel (optional)

(Three phase EI laminated power transformer)

Designed according to the latest European EN 50171 emergency lighting specifications

True double-conversion and PWM technology

Including inverter-level output current isolation transformer

Up to 91% efficiency

Can withstand 120% continuous overload, in line with European emergency lighting regulations

Large charger for faster battery charging

Maintenance bypass (used to completely isolate the inverter during maintenance)

Unique inverter design suitable for high surge lighting loads

User selection of bypass loading (switching mode)

LCD panel provides accurate detailed information about load, battery, and inverter, and has advanced diagnostic functions

RS232 and dry contacts for communication and remote monitoring

To solve the problem of distortion of the output waveform of the three-phase static inverter, the voltage distortion caused by the dead zone effect and the generated harmonic components are analyzed in detail. A control method is proposed, which sets the dead time and voltage compensation. To improve the inverter output, a notch filter and a low-pass filter cascade filter circuit are designed on the converter output.

Adjust the output according to the power/load changes, the output power is in line with MIL-STD-704, reverse input voltage protection, use the output surge capacity to start the motor, the qualified temperature range is -55?to 85? and it can be automatically shut down for Input overvoltage protection, equipped with automatic current limiting and recovery protection, to prevent overload and short circuit, without maintenance.

Static inverters are generally used in the following scenarios: fixed-wing and rotary-wing aircraft, weapon systems, drive motor loads, and replacement of motor-generator sets.

Static inverters are commonly used to provide power for frequency sensitive instruments such as attitude gyroscopes and directional gyroscopes. They also provide power for automatic synchronization and magnetic synchronization indicators and transmitters, rate gyroscopes, radar, and other airborne applications.