Lithium iron phosphate battery refers to a lithium-ion battery using lithium iron phosphate as a positive electrode material. The positive electrode materials of lithium-ion batteries mainly include lithium cobaltate, lithium manganate, lithium nickelate, ternary materials, and lithium iron phosphate. Among them, lithium cobalt oxide is the cathode material used in most lithium-ion batteries.

Lithium iron phosphate battery is used to make a lithium-ion secondary battery. A lithium battery is a kind of battery that uses lithium metal or lithium alloy as a positive electrode material and uses a non-aqueous electrolyte solution. The chemical characteristics of lithium metal are very active, which makes the processing, storage, and use of lithium metal very demanding on the environment. The energy density of lithium iron phosphate batteries is not as great as that of lithium-ion batteries. The voltage is also relatively low.

The electrochemical performance of the positive electrode material of lithium iron phosphate battery is relatively stable, which determines that it has a stable charge and discharge platform, therefore, the structure of the battery will not change during the charge and discharge process, will not burn and explode, and even in short circuit, excessive It is still very safe under special conditions such as charging, squeezing and acupuncture. Lithium iron phosphate batteries do not contain any heavy metals and rare metals, are safe, non-toxic and non-polluting, and are absolutely green and environmentally friendly batteries. Because the lithium iron phosphate material is clean and non-toxic throughout the production process, all raw materials are non-toxic and non-polluting.

When a lithium iron phosphate battery is charged, lithium ions in the positive electrode migrate to the negative electrode through the polymer separator; during discharge, lithium ions in the negative electrode migrate to the positive electrode through the separator. Lithium-ion batteries are named because lithium ions migrate back and forth during charging and discharging. The charge-discharge reaction of the lithium iron phosphate battery is carried out between the two phases of LiFePO4 and FePO4. During charging, LiFePO4 gradually detaches from lithium ions to form FePO4, and during discharge, lithium ions intercalate into FePO4 to form LiFePO4. When the battery is charged, lithium ions migrate from the lithium iron phosphate crystal to the crystal surface, enter the electrolyte under the action of electric field force, then pass through the separator, and then migrate to the surface of the graphite crystal through the electrolyte, and then embedded in the graphite lattice.

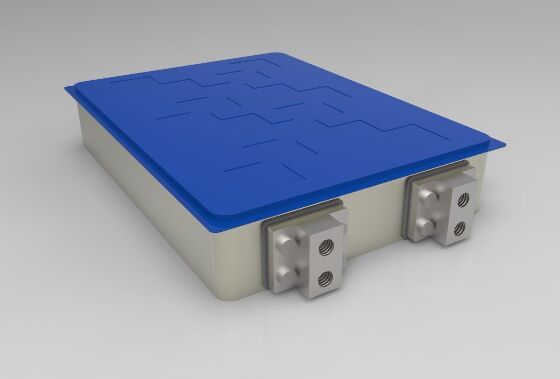

The left side of the lithium iron phosphate battery is a positive electrode composed of LiFePO4 material of olivine structure, which is connected to the positive electrode of the battery by aluminum foil. On the right is the negative electrode of the battery made of carbon (graphite), which is connected to the negative electrode of the battery by copper foil. In the middle is a polymer separator, which separates the positive electrode from the negative electrode. Lithium ions can pass through the separator and electrons cannot pass through the separator. The battery is filled with electrolyte, and the battery is hermetically sealed by a metal casing. Lithium iron phosphate battery has the advantages of high working voltage, large energy density, long cycle life, good safety performance, small self-discharge rate, and no memory effect.

The synthesis process of lithium iron phosphate has been perfected, mainly divided into a solid-phase method and liquid-phase method. Among them, the high-temperature solid-phase reaction method is the most commonly used, and some researchers have combined the microwave synthesis method in the solid phase method and the hydrothermal synthesis method in the liquid phase method-microwave hydrothermal method.

The synthesis methods of lithium iron phosphate also include bionic method, cooling drying method, emulsification drying method, pulse laser deposition method, etc. By selecting different methods, synthesizing products with small particle size and good dispersion performance can effectively shorten the diffusion path of Li+ As the contact area between the two phases increases, the diffusion rate of Li+ increases.

In the charging phase, the intermittent power supply or power grid charges the energy storage system. (12V/24V/48V to 110V/220V AC power inverter PI plus series)After the AC power passes through the rectifier, it is rectified into DC power to charge the energy storage battery module and store energy. In the discharge phase, the energy storage system discharges the power grid or load. The DC power is converted to AC power by the inverter, and the inverter output is controlled by the central monitoring system, which can provide stable power output to the grid or load.

Lithium iron phosphate batteries will break if they are left uncharged for too long, so you need to charge the batteries from time to time to prolong their service life. If the lithium iron phosphate battery is dead, and it is left unused or charged for a long time, it will cause the lithium iron phosphate battery to fail because it is too low and cannot be used again. The battery that often drains the lithium iron phosphate battery, The lifespan is at least 50% shorter than that of regular charging.

Effective storage of lithium iron phosphate battery can ensure the extension of its service life, so what is the correct storage method?

Lithium iron phosphate batteries include lithium alloy batteries) and lithium-ion batteries (including lithium-ion polymer batteries). All lithium iron phosphate batteries (groups) must pass the UN38.3 test and issue a test report; storage temperature requirements for conventional lithium iron phosphate batteries To be within 18-25 degrees, this is the same as the transportation temperature control requirements. If there are differences, corresponding coordination and technical maintenance can be done according to product characteristics. The environment of the warehouse is easy to be moderately ventilated and dry. It can effectively control the humidity of the warehouse and avoid the warehouse being exposed to high humidity for a long time (relative humidity is higher than 90% or lower than about 40%), and physical treatment can be carried out if necessary (note safety). Lithium iron phosphate battery warehouses are separated by physical protective walls, equipped with explosion-proof facilities and safety lighting facilities and necessary fire protection equipment (check whether they are fully available at regular intervals). The warehouse is heavily banned from smoking and fire, including high-temperature operations or other operations that cause fires near the warehouse site.

It can be used for three-dimensional shelf storage according to the technical requirements of the product itself, which is conducive to cost control and the use of storage space. Lithium iron phosphate battery storage should avoid deformation caused by stacking and squeezing or battery product damage and subsequent leakage. Lithium iron phosphate batteries should be stored away from direct sunlight or rain. The battery will be exposed to rain, the insulation resistance will be reduced, and self-discharge and chlorination may occur. Lithium iron phosphate batteries should be waterproof and dustproof during use, so there should be no water in the storage area, which will affect the performance and service life of the battery. The temperature rise then damages the normal function of the battery. Use packaging that conforms to safe storage or transportation, such as common wooden boxes, corrugated cardboard boxes, or PVG boxes, etc., to ensure the maximum safe storage of goods. To the greatest extent, eliminate the friction collision and throwing caused by field operations, avoid accidents such as combustion and explosion, and do the corresponding isolation operations. A variety of emergency plans for lithium iron phosphate battery accidents have been formulated, and regular drills can be conducted if conditions permit.

Lithium iron phosphate battery has a series of unique advantages such as high working voltage, high energy density, long cycle life, low self-discharge rate, no memory effect, green environmental protection, etc., and supports stepless expansion, suitable for large-scale electrical energy storage, renewable energy power stations have good application prospects in areas such as safe grid connection for power generation, peak shaving of power grids, distributed power stations, UPS power supplies, and emergency power supply systems.(Line interactive UPS-AK LCD series)

(1) Constant voltage charging method: During the charging process, the output voltage of the charging power supply remains constant. With the change of the state of charge of the lithium iron phosphate battery pack, the charging current is automatically adjusted. If the prescribed constant voltage value is appropriate, it can not only ensure the full charge of the power battery but also minimize gas evolution and water loss. This charging method only considers the single-state change of battery voltage, and cannot effectively reflect the overall charging status of the battery. Its initial charging current is too large, often causing damage to the power battery. Beceuse of this shortcoming, constant voltage charging is rarely used.

(2) Constant current charging method: During the entire charging process, the charging current is kept constant by adjusting the output voltage. Keeping the charging current unchanged, the charging rate is relatively low. The constant current charging control method is simple, but because the acceptable current capacity of the lithium battery pack gradually decreases as the charging process progresses, by the later stage of charging, the power receiving capacity of the power battery decreases, and the charging current utilization rate is greatly reduced. The advantage of this method is that it is simple, convenient, and easy to implement, and the charge capacity is easy to calculate.

(3) Constant current and constant voltage charging method: This charging method is a simple combination of the above two. The first stage uses a constant current charging method to avoid excessive charging current at the beginning of constant voltage charging. The second stage uses the constant voltage charging method to avoid the phenomenon of overcharging caused by constant current charging. Lithium iron phosphate battery packs, like any other sealed rechargeable battery, must be controlled for charging, and cannot be overcharged, otherwise, the battery will be easily damaged. Lithium iron phosphate batteries generally use the charging method of constant current first and then voltage limiting.

(4) The chopping charging method: the chopping method is used for charging. In this method, the current of the constant current source is unchanged, and the switch is controlled to turn it on for some time and then turn off for some time. The advantage of this method is that when the battery is charged through an external circuit, Ion generation within the battery requires a certain response time, and if it is continuously charged, it may reduce the potential of its capacity. After charging for some time, adding a turn-off time can allow the ions generated by the two poles of the battery to have a diffusion process, so that the battery has a "digestion" time, which will greatly increase the utilization rate of the battery and improve Charging effect.

To better use lithium iron phosphate batteries and protect the environment, how should we recycle used batteries?

The recycling of used lithium-ion batteries is the process of extracting useful metals from the batteries. The recycling of waste lithium-ion batteries is mainly divided into two categories: one is to recycle precious metals; the other is regenerative lithium-ion battery materials. Recycling process: Lithium-ion batteries are first discharged, and then separated into different parts such as positive and negative electrodes and separators through pretreatment processes such as disassembly, crushing and separation, and then different chemical, physical or biological processes are used for different electrode materials. Recycle the useful parts.

The charger of the lithium iron phosphate battery pack is different from the ordinary lithium battery. The maximum termination charging voltage for lithium batteries is 4.2 volts; the lithium iron phosphate battery pack is 3.65 volts. When the lithium iron phosphate battery pack is charged, it is the cable connected to the balance charging board. Generally, it is directly charged in series from both ends. The charger voltage is greater than the battery pack voltage. The cable detects the voltage of each cell, which is equivalent to connecting a voltage regulator tube in parallel. The charging voltage of the cell will not exceed the voltage regulation value, while the other cell batteries continue to charge through the voltage regulator bypass charging.

Because the power of each cell is nearly full at this time, it is just balancing each cell, so the charging current is small, and each cell is supplemented and balanced to be full. The charger can only protect the end voltage of the entire battery pack. The balanced charging board ensures that each cell is overcharged and each cell is fully charged. The charging of the entire lithium battery pack cannot be stopped because one cell is full.

There are three main types of recycling methods for waste lithium batteries: physical, chemical, and biological methods. Compared with other methods, hydrometallurgy is considered to be an ideal recovery method because of its low energy consumption, high recovery efficiency, and high product purity.

①Physical method: Use the physical and chemical reaction process to process the lithium iron phosphate battery. Common physical and chemical treatment methods are mainly crushing flotation and mechanical grinding.

②Chemical method: The method of a processing lithium battery by a chemical reaction process is generally divided into two methods: pyrometallurgy and hydrometallurgy.

③ Biological method: The metallurgical method is currently under study. It uses the metabolic process of microbial fungi to achieve selective leaching of metal elements such as cobalt and lithium. The biological method has low energy consumption, low cost, and microbes can be reused with little pollution; however, the cultivation of microorganisms requires harsh conditions, long cultivation time, low leaching efficiency, and the process needs to be further improved.